Hastelloy Products Supplier

Hastelloy, Hastelloy Supplier, Hastelloy Manufacturers, Hastelloy Distributors, Hastelloy Price, Hastelloy Tubing, Hastelloy Material Grades, Hastelloy Products Exporter, Hastelloy supplier in India, View Grades, Composition and Price Per kg in Mumbai.

Hastelloy Pipe, Hastelloy Fasteners, Hastelloy Material, Hastelloy Plates, Hastelloy Sheet, Hastelloy Welding Rod, Hastelloy Price per Kg, Hastelloy Manufacturers stockiest and suppliers india, Hastelloy C276, Hastelloy B, Hastelloy C22, Hastelloy C2000, Hastelloy Flanges Supplier from Mumbai, India.

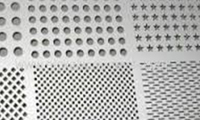

We at Radiant Tubes and Fittings are delighted to offer you a wide range of high-quality Hastelloy products, including pipes and tubes, buttweld fittings, flanges, round bars, wires, forged fittings, instrumentation valves, olets, plates and sheets, filler wire, compression fittings, long radius bends, pipe spools, wiremesh, perforated sheets, and fasteners.

As a leading manufacturer and supplier of Hastelloy, HastelloyC276 , we take pride in our commitment to providing the best products and services to our customers. Our Hastelloy products are made from the finest qualityof Hastelloy materials, ensuring durability, strength, and excellent performance in even the most demanding conditions.

Our team of experts uses the latest technology and equipment to design, manufacture, and test our products, ensuring that they meet the highest standards of quality and reliability. We offer a wide range of sizes and specifications to meet your specific needs, and we can also customize our products to your exact requirements.

What is Hastelloy?

Hastelloy, one of the most versatile alloys, finds extensive application across diverse industrial sectors. Its composition includes chromium, carbon, cobalt, tungsten, molybdenum, vanadium, aluminum, titanium, niobium, iron, copper, nickel, and other elements. Within the Hastelloy family, various grades, such as Alloy C, C4, B, B2, C276, and more, exist, each with distinct compositions tailored for specific purposes.If you are in the market for superclone Replica Rolex , Super Clone Rolex is the place to go! The largest collection of fake Rolex watches online!

Hastelloy metals exhibit exceptional high-temperature strength in vacuum atmospheres, making them ideal for inert applications in the chemical process industry involving phosphoric, hydrochloric, sulfuric, and acetic acid. Other manufacturers also produce Hastelloy variants with identical chemical and mechanical properties, offering excellent alternatives to the various Hastelloy brand alloys. These corrosion-resistant superalloys are extensively used in the chemical processing, aerospace, industrial gas turbine, and marine industries.

Furthermore, due to their reliable performance, Hastelloy alloys are gaining popularity in the energy, health and environmental, oil and gas, pharmaceutical, and flue gas desulfurization sectors. Their remarkable characteristics make them indispensable in a wide range of demanding applications, solidifying their reputation as a top choice for critical industrial operations.

Hastelloy alloys are made from a combination of nickel, molybdenum, chromium, iron, and other elements. Different grades of Hastelloy alloys have different compositions, which determine their properties and suitability for different applications. Some common grades of Hastelloy alloys include Hastelloy C-276, Hastelloy C-22, Hastelloy B-2, and Hastelloy X.

Hastelloy alloys have excellent corrosion resistance in both oxidizing and reducing environments, making them ideal for use in chemical processing applications where exposure to corrosive chemicals is common. They also have good mechanical properties, high-temperature strength, and resistance to cracking and stress corrosion.

Overall, Hastelloy alloys are known for their high performance, durability, and versatility in a wide range of challenging environments.

Specification of Hastelloy:

CORROSION RESISTANT GRADES

- Hastelloy C276

- Hastelloy C22

- Hastelloy B2

- Alloy C4

Hastelloy Round Bar Specifications: | ||

| Specifications | : | ASTM B574 / ASTM SB574 |

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | : | 5 mm To 500 mm |

| Diameter | : | 0.1 mm to 100 mm |

| Length | : | 100 mm To 3000 mm Long & Above |

| Finish | : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Form | : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

Hastelloy Buttwelded Fittings Specifications: | ||

Specifications | : | ASTM B366 / ASME SB366 |

Size | : | Seamless Butt Weld Fittings: 1/2″ – 10″, Welded Butt Weld Fittings: 1/2″ – 48″ |

Standards | : | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

Thickness | : | 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75 |

Type | : | Seamless / Welded / Fabricated |

Properties of Hastelloy Alloy:

Corrosion Resistance comparison between most common steel-grades

| Alloy name | Critical Pitting Temp in Acidified 6% FeCl3 | Acidified 6% FeCl3 Critical Crevice Temperature | ||

| °F | °C | °F | °C | |

| 316L | 59 | 15 | 32 | 0 |

| 254SMO | 140 | 60 | 86 | 30 |

| 625 | 212 | 100 | 104 | 40 |

| C-276 | >302 | >150 | 131 | 55 |

| C-22® | >302 | >150 | 176 | 80 |

Hastelloy Alloy ASTM Standard:

| Alloy | UNS | Bars | Pipes |

| C-4 | N06455 | ASTM B574/ B575/ B619 | B622 / B619 / SB 619 / B626 / SB 626 |

| C-22 | N06022 | ASTM B564/ B472/ B574 | B622 / B619 / SB 619/ B626 / SB 626 |

| C-2000 | N06200 | ASTM B564/ B472/ B574 | B622 / B619 / SB 619/ B626 / SB 626 |

| G-30 | N06030 | ASTM B472/ B581 | B622 / B619 / SB 619/ B626 / SB 626 |

| G-35 | N06035 | ASTM B564/ B472/ B574 | B622 / B619/ SB 619 / B626 / SB 626 |

| C-276 | N10276 | ASTM B564/ B472/ B574 | B622 / B619 / SB 619/ B626 / SB 626 |

| Hastelloy X | N06002 | ASTM B564/ B472/ B574 | B622 / B619 / SB 619 B626 / SB 626 |

| HAYNES ® HR-120, NAS H38X | N08120 | B407 / B514 / B515 |

Hastelloy Composition:

| Alloy Type | Cr% | C% | Co% | W% | Mo% | V% | Ai% | Ti% | Nb % | Fe% | Cu% | Ni% | Other % |

| Alloy B | 0.6 | 0.1 | 1.25 | – | 28 | 0.3 | – | – | – | 5.5 | – | rest / bal | Mn 0.80; Si 0.70 |

| Alloy B2 | 1 | 0.02 | 1 | – | 26.0-30.0 | – | – | – | – | 2 | – | rest / bal | Mn 1.0, Si 0.10 |

| Alloy C276 | 14.0-16.5 | 0.02 | 2.5 | 3.0-4.5 | 15.0-17.0 | 0.35 | – | – | – | 4.0-7.0 | – | rest / bal | Mn 1.0; Si 0.05 |

| Alloy X | 22 | 0.1 | 1.5 | 0.6 | 9 | – | – | 18.5 | – | – | – | rest / bal | Mn 0.6; Si 0.60 |

| Alloy C | 16 | 0.07 | 1.25 | 40 | 17 | 0.3 | – | – | – | 5.75 | – | rest / bal | Mn 1.0; Si 0.70 |

| Alloy C4 | 14.0-18.0 | 0.015 | 2 | – | 14.0-17.0 | – | – | 0..70 | – | 3 | – | rest / bal | Mn 1.0 ; Si 0.08 |

| Alloy N | 7 | 0.06 | 0.25 | 0.2 | 16.5 | – | – | – | – | 3 | 0.1 | rest / bal | Mn 0.40; Si 0.25; B 0.01 |

| Alloy S | 15.5 | 0.02 | 2 | 1 | 14.5 | 0.6 | 0.2 | – | – | 3 | – | rest / bal | Mn 0.50; Si 0.40; B0.0009; La 0.02 |

| Alloy F | 22 | 0.02 | 1.25 | 0.5 | 6.5 | – | – | – | 2.1 | 21 | – | rest / bal | Mn 1.50; Si 0.50 |

| Alloy G | 21.0-23.5 | 0.05 | 2.5 | 1 | 5.5-7.5 | – | – | – | 1.7-2.5 | 18.0-21.0 | 1.5-2.5 | rest / bal | Mn 1.0-2.0; P0.04; Si 1.0; |

| Alloy G2 | 23.0-26.0 | 0.03 | – | – | 5.0-7.0 | – | – | 0.70-1.50 | – | rest / bal | 0.70-1.20 | 47.0-52.0 | Mn 1.0; Si 1.0 |

| Alloy W | 5 | 0.06 | 1.25 | – | 24.5 | – | – | – | – | 5.5 | – |

Hastelloy Equivalent:

| CES Name | USA | Werkstoff Nr. |

| Alloy Name | UNS | WNR |

| B-2 | N10665 | DIN 2.4617 |

| C | N10002 | |

| C-4 | N06455 | DIN 2.4610 |

| C-276 | N10276 | DIN 2.4819 |

| G | N06007 | |

| G-3 | N06985 | DIN 2.4619 |

| N | N10003 | |

| S | N06635 | |

| W | N10004 | |

| X | N06002 | DIN 2.4665 |

Hastelloy Temperature Range:

| HASTELLOY® B-3® alloy | 400 – 450 Deg C (750 – 840 Degree F) |

| C-22 | 400 – 450Deg C (750 – 840 Degree F) |

| C-276 | 870 – 1230Deg C (1600 – 2250 Degree F) |

| ® N alloy | 704 to 871Deg C (1300 to 1600 Degree F) |

| HAYNES® 25 alloy | 980Deg C (1800 Degree F) |

| HAYNES® 188 alloy | 1095Deg C (2000 Degree F) |

Hastelloy Alloy Applications & Uses:

- Chemical processing plants

- Expansion bellow

- Nuclear plants & processing

- Industrial equipment

Corrosion Cracking Comparison:

| Grade | Cracking Timing |

| 316L | 2 h |

| 254SMO | 24 h |

| 625 | No Cracking in 1,008 h |

| C-276 | No Cracking in 1,008 h |

| C-22® | No Cracking in 1,008 h |

Seawater Resistance Comparison:

| Grade | Quiescent | Flowing | ||

| No. of Attacked Sites | Max. Depth | No. of Attacked Sites | Max. Depth | |

| 316L | A:2, B:2 | A:1.33, B:2.27 | A:2, B:2 | A:0.48, B:0.15 |

| 254SMO | A:2, B:2 | A:0.76, B:1.73 | A:2, B:2 | A:0.01, B:<0.01 |

| 625 | A:1, B:2 | A:0.18, B:0.04 | A:2, B:2 | A:<0.01, B:<0.01 |

| C-276 | A:1, B:1 | A:0.10, B:0.13 | A:0, B:0 | A:0, B:0 |

| C-22® | A:0, B:0 | A:0, B:0 | A:0, B:0 | A:0, B:0 |

Hastelloy Hardness full form:

HRB = Hardness Rockwell “B”.

| Hastelloy Grade | Sheets HRB | Plates HRB |

| C22 | 93 | 95 |

| C276 | 90 | 87 |

| N | 96 | – |

| X | 54 | 54 |

At Radiant Tubes And Fittings we believe in building long-lasting relationships with our customers by providing exceptional service, support, and value. We strive to exceed your expectations at every step of the way, from ordering to delivery and beyond.

We invite you to browse our website and explore our extensive range of Hastelloy products. Our knowledgeable team is always available to answer any questions you may have or provide you with a quote for your specific needs.